Why Is My ID Card Print Quality Poor or Blurry?

ID card printers are a critical part of many organizations' daily operations, especially when it comes to security, identification, and professionalism. But when the ID card print quality of your ID cards turns out poor or blurry, it’s not just frustrating—it can lead to delays, wasted supplies, and even security risks.

In this detailed guide, we’ll explore the most common reasons behind poor ID card print quality, what you can do to fix it, and how to prevent it from happening in the future. Whether you're printing employee badges, student IDs, or visitor passes, this troubleshooting article will help you get your card printer back on track.

Common Symptoms of Poor ID Card Print Quality

Before jumping into the causes, let's define what poor ID card print quality might look like:

Blurry or fuzzy text and images

Smudges, streaks, or faded spots

Uneven color distribution

Ghosting or shadows

Poor edge-to-edge printing

If you’re experiencing one or more of these issues, it’s time to go through a step-by-step analysis of what might be causing the problem.

1. Dirty or Contaminated Printer Components

The most common cause of poor ID card print quality is a lack of proper cleaning. Dust, oil, and debris from the environment or from the cards themselves can build up on the printer's rollers and printhead. This contamination affects how well the ribbon adheres to the card surface, leading to smudges and streaks.

Fix:

Use a manufacturer-approved cleaning kit.

Clean the printer regularly—ideally every 1,000 cards or as specified in your user manual.

Always clean the rollers and printhead, not just the surface.

2. Low-Quality or Damaged Blank Cards

Poor quality blank cards can drastically affect ID card print quality. Inconsistent card surfaces or damaged edges can cause misfeeds, ribbon tears, and blurred prints.

Fix:

Always use high-quality, ISO-compliant blank cards.

Inspect cards for warping, scratches, or manufacturing defects before loading.

Store cards in a dust-free, temperature-controlled environment.

3. Incorrect Printer Settings

Your printer settings play a big role in ID card print quality. Using the wrong ribbon configuration or resolution can cause your cards to look washed out or blurry.

Fix:

Check your driver and design software settings.

Ensure the ribbon type selected matches the ribbon installed (e.g., YMCKO, YMCKOK, etc.).

Use 300 or 600 DPI print settings for best clarity.

Enable edge-to-edge printing if your design requires it.

4. Using the Wrong Ribbon Type

Using a ribbon that is not compatible with your printer model or card type can result in extremely poor ID card print quality. Common issues include color misalignment, washed-out images, or partial prints.

Fix:

Always verify the ribbon type matches your printer model.

Check the ribbon cartridge for signs of damage or low supply.

Replace the ribbon if it has dried out or if it’s nearing the end of its life cycle.

5. Dirty or Misaligned Printhead

The printhead is responsible for transferring the image from the ribbon onto the card. If the printhead is dirty, misaligned, or damaged, it will result in inconsistent ID card print quality.

Fix:

Clean the printhead using isopropyl alcohol and a lint-free swab.

Check for alignment in your printer’s maintenance settings.

If damage is visible, contact your service provider for a replacement.

6. Incorrect Card Thickness Settings

If your printer isn’t adjusted to the thickness of your card, the printhead pressure and ribbon feed may be off, which directly impacts ID card print quality.

Fix:

Check your printer settings for card thickness (most printers allow 20–40 mil).

Match the setting with your card stock.

Run a test card to confirm improvements.

7. Environmental Conditions

Believe it or not, temperature and humidity can affect how well your printer performs. Thermal printers are particularly sensitive to extreme conditions, which can cause poor ID card print quality.

Fix:

Operate the printer in a climate-controlled environment (ideally 20–25°C with 40–60% humidity).

Avoid printing near windows, heat sources, or dusty areas.

8. Software or Driver Issues

Outdated drivers or bugs in the design software can cause the printer to misinterpret your design file, leading to degraded ID card print quality.

Fix:

Update your printer driver to the latest version from the manufacturer’s website.

Reinstall or update your card design software.

Run a built-in test print from the printer menu to isolate whether the issue is with software or hardware.

9. Improper Handling of Supplies

Touching blank cards or the printing surface of the ribbon with bare hands can leave oils and residues that impact ID card print quality.

Fix:

Always handle blank cards by the edges.

Wear gloves when loading ribbons or cards if possible.

Store all supplies in their original packaging when not in use.

10. The Printer Is Reaching End of Life

If your printer is several years old and you've tried all the above steps, poor ID card print quality could simply be a result of worn components or outdated technology.

Fix:

Check the manufacturer’s expected lifespan for your model.

Consider upgrading to a newer model with retransfer printing or lamination options for improved durability and clarity.

Speak with an ID solutions provider for a quote on trade-in or rental programs.

Bonus Tip: Use a Retransfer Printer for Higher Quality

Retransfer printers offer superior print quality by printing the image onto a clear film which is then fused to the card. This method provides:

True edge-to-edge printing

Better coverage on uneven surfaces (smart cards, RFID chips)

Longer-lasting, high-resolution images

If print quality is critical for your organization, especially in healthcare, government, or enterprise security, investing in a retransfer printer like the HID Fargo HDP6600 may be the best long-term solution.

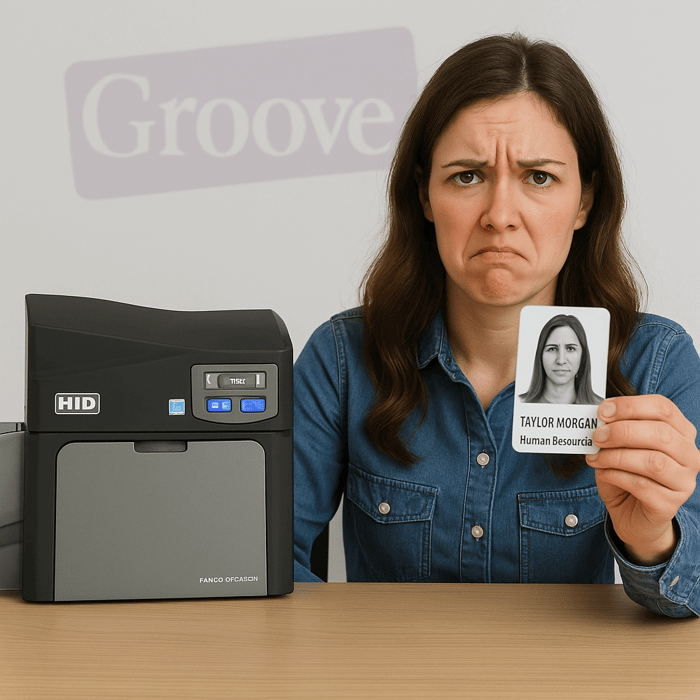

Final Thoughts: Don’t Let Poor Print Quality Hurt Your Brand

Your ID cards are often the first impression visitors, staff, and customers get of your organization. Poor print quality can project unprofessionalism and even cause operational issues like unreadable barcodes or security risks.

At Groove Identification Solutions, we help businesses across Canada solve issues just like this every day. Whether you need help with printer maintenance, cleaning supplies, or upgrading your equipment, our team is here to support you.

We offer:

Free troubleshooting support

Cleaning kits and printer ribbons

High-quality PVC and technology cards

Expert advice on printer upgrades or rentals

Get Help With Your Card Printer Today

Still struggling with poor ID card print quality? Contact Groove Identification Solutions for expert advice or explore our full range of card printer supplies and support services.

Visit: www.groovebadges.com

Call: 1-888-940-3645

Email: info@groovebadges.com